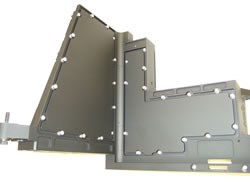

Assembly

R E Thompson offer a turnkey manufacturing solution including the finishing & assembly of components and operate a dedicated assembly section with a clean area policy.

The dedicated assembly department is equipped with a curing oven, pressing tools and bench top tooling as well as specialist machines for helicoiling. We also offer specialist bonding and sealing services as part of their complete manufacturing services as detailed below.

Bonding

Bonding can be carried out betwen rubber, foam, plastic, fabric and metal under controlled conditions. We operate a MIDO 6 oven for controlled curing and are able to test adhesive strength prior to delivery

Form-In-Place (FIP) Gaskets

Developed in response to demand from high profile telecommunications and electronics manufactures, R E Thompson have developed a robotic solutionfor placement of form in place gaskets suitable for water tight electronic applications and temperature sensitive assemblies. The robotic CNC dispenser is programmable offline and operates to a high level of precision suitable for forming complex gasket shapes directly onto the component

Finishing

R E Thompson offer a number of in-house finishing options although as part of their one-stop shop flexible manufacturing service they provide a range of other processes through well established business partners

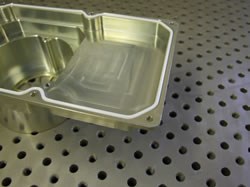

Machined Finishes

Precision finishes can be achieved through the use of high speed tooling at slow feed rates or by use of specialist diamond and polishing cutting tools. Whether you are looking for flush mating surfaces or an aesthetic finish we can offer a range of varied machined finishes to suit your requirements

Vacuum Bead Blasting

We offer vacuum bead blasting for adding a polished finish to aluminium and steel surfaces. Vacuum bead blasting ensures that no material is left on the component part, a critical requirement for high specification applications. Our bead blasting cabinet is suitable for components up to 600mm x 400mm x 400mm and under 50kg

Engraving

Engraving can be carried out inhouse on the CNC machines although for specialist engraving with infills we work closely with a well establish outsourced sub-contractor

Degreasing

Hand cleaning with a degreasing agent can be carried out inhouse either prior to shipping or before surface coating with a stove enamel or powder finish

Deburring

Manual deburring can be undertaken inhouse